DIE GRINDER

Die grinders and rotary tools are handheld power tools used for grinding, sanding, honing, polishing, or machining material (typically metal, but also plastic or wood). All such tools are conceptually similar, with no bright dividing line between die grinders and rotary tools, although the die grinder name tends to be used for pneumatically driven heavy-duty versions whereas the rotary tool name tends to be used for electric lighter-duty versions.

DCA SPECIFICATION :

- 50-60 Hz

- 400 W

- 220-240 V

- Ø25 MM

DONGCHEN SPECIFICATION :

- 50-60 Hz

- 400 W

- N 2700R/MIN

- Ø25 MM

DIE GRINDER

Die grinders and rotary tools are handheld power tools used for grinding, sanding, honing, polishing, or machining material (typically metal, but also plastic or wood). All such tools are conceptually similar, with no bright dividing line between die grinders and rotary tools, although the die grinder name tends to be used for pneumatically driven heavy-duty versions whereas the rotary tool name tends to be used for electric lighter-duty versions.

MAKITA SPECIFICATION :

- 50-60 Hz

- 1.8 A

- 230-240 V

- N 25000/MIN

HITACHI HOKI SPECIFICATION :

- 50-60 Hz

- 2888 W

BENCH GRINDER

A bench grinder is a benchtop type of grinding machine used to drive abrasive wheels. A pedestal grinder is a similar or larger version of grinder that is mounted on a pedestal, which may be bolted to the floor or may sit on rubber feet. These types of grinders are commonly used to hand grind various cutting tools and perform other rough grinding.

SPECIFICATION :

- 240 V

- 22 M/S

- 2800/MIN

- Ø150 MM

- 50 Hz

- 250 watt

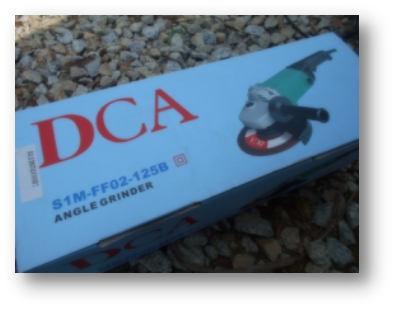

ANGLE GRINDER

An angle grinder, also known as a side grinder or disc grinder, is a handheld power tool used for grinding (abrasive cutting) and polishing. Although developed originally as tools for rigid abrasive discs, the availability of an interchangeable power source has encouraged their use with a wide variety of cutters and attachments.

SPECIFICATION :

- Rated Power Input (w) 1200

- Rated Speed (r/min) 11800

- Wheel Aperture (mm) Ø22

- Max. Wheel Diameter (mm) Ø125

- Weight (kg) 3.0 kg

- Carbon Brush DC-H043

WELDING GENTIG 250 PULSE (AUWELD)

Gentig 250 Pulse is a compact, lightweight and portable for the workshop or job site. It operates from a standard 230V, 13A, 16A power point. This product also runs a wide range of electrodes from 1.6 mm to 4.0 mm. with its single-dial adjustable welding current allowing infinite current control.

WELDING TIG 300 (MELLO)

TIG stands for Tungsten Inert Gas and is technically called Gas Tungsten Arc Welding. The process uses a non-consumable tungsten electrode that delivers the current to the welding arc. The tungsten and weld puddle are protected and cooled with an inert gas, typically argon. TIG welding is similar to oxy-acetylene welding in that you use a filler material for build-up or reinforcement.

SPECIFICATION :

- 10 A/10.4 V

- 300 A / 22 V

- 50-60 Hz

WELDING TIG 300S (MELLO)

TIG stands for Tungsten Inert Gas and is technically called Gas Tungsten Arc Welding. The process uses a non-consumable tungsten electrode that delivers the current to the welding arc. The tungsten and weld puddle are protected and cooled with an inert gas, typically argon. TIG welding is similar to oxy-acetylene welding in that you use a filler material for build-up or reinforcement.

SPECIFICATION :

- 50-60 Hz

- 230 V

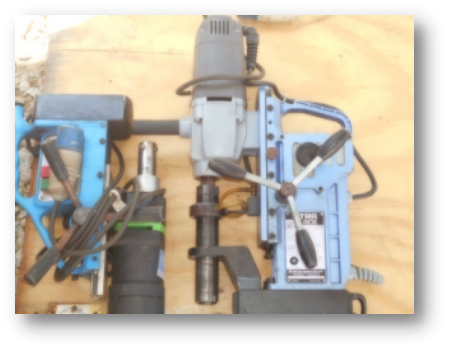

MAGNETIC MOTOR DRILL MODEL AO-5575

A Magnetic Drilling Machine is a portable drilling machine with a magnetic base (either electromagnetic or permanent magnet). It uses standard twist drill bits, and some can also be used with annular cutters, milling cutters and other rotary cutters.

SPECIFICATION :

- 220-240 V

- 50-60 Hz

- 1150 W

- 5.4 A

- Weight : 18 kg

PORTABLE WELDING ELECTRODE DRYER

Most of the welding electrodes, particularly the Low Hydrogen Iron Powder Type Electrodes may absorb moisture from the atmosphere. If the moisture is excess than the recommended level consistent with the type of flux, the electrodes should be re-dried before use for one hour at 0-250 Deg Celsius, to drive away any absorbed excess moisture from the flux coating.

SPECIFICATION :

- Model : KS-5-450

- AC 230 V

- 50 Hz

- 180 °C, 20 °C

–Back